Titanium Diffusion Hardening

Titanium Diffusion Hardening Creates a Superior Bearing Surface

TITANIUM HARDENING CREATES A SUPERIOR BEARING SURFACE

Titanium Diffusion Hardening (TDH) is an innovative and proven surface hardening technology from Kamatics.

- Utilizes a diffusion process to create a hardened case layer within the original titanium article (not a coating).

- Hardness of 60 Rockwell C

- Case layer depth .008” or 200 microns

- Creates a smooth hard bearing surface in titanium alloys

Makes Titanium Viable for High Wear, High Load Applications

Untreated titanium boasts a high strength to weight ratio, performs well at high temperatures, and is very resistant to corrosion. However, when compared to steels, it has a relatively low hardness level and tendency to gall and seize under high loads or while sliding. TH treatment eliminates these problems and improves wear and friction properties in bearing applications.

TDH is the best option to take advantage of weight savings offered by Titanium for high-load or high-wear applications.

Click here and learn more about the TDH process and applications.

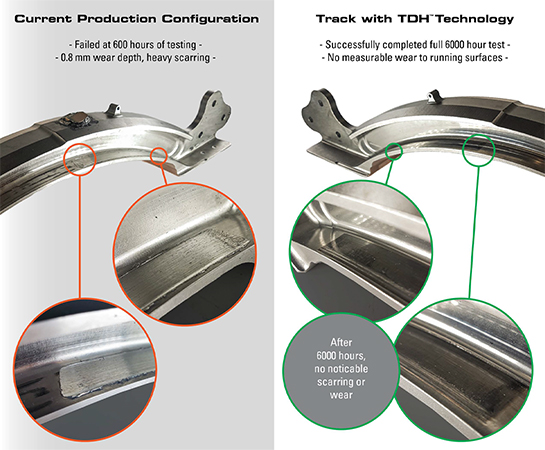

Slat Tracks With Tdh Technology Will Last the Life of Your Aircraft

Download the test report.

Titanium Diffusion Hardening is a proprietary surface treatment process that creates a deep case layer (not a coating) in titanium alloys. Employing a Kamatics track roller with a slat track treated with TDH creates a tribological system which is extremely wear resistant, and has been proven to extend component life by more than 10x over the untreated Titanium track condition.

OTHER EXCEPTIONAL KAMATICS INNOVATIONS

KAron™ Liner Options

Custom Engineering